Your customers operate in a digital world — and they increasingly expect OEMs to deliver actionable insights derived from real machine performance and usage.

Tier One OEMs invest millions every year in proprietary software development to stay connected to their products. They understand how the equipment is used and when service is required.

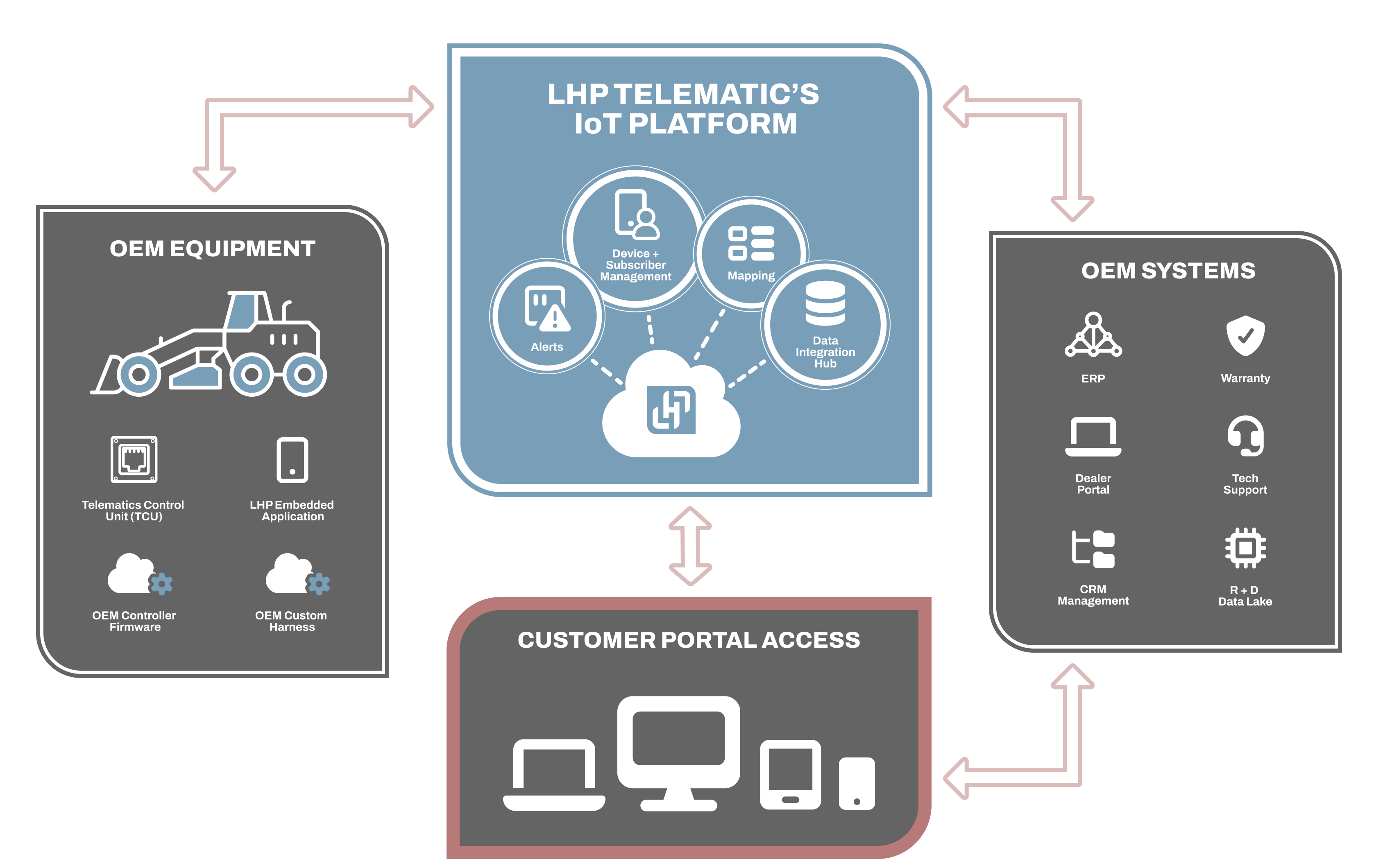

LHP’s highly configurable IoT telematics platform gives your product teams the power to create a differentiated, branded customer experience at a fraction of the cost of building it yourself.

Make Data-Driven

Engineering Decisions

Accelerate innovation using real-world machine data. Our platform enables OEMs to efficiently collect large statistical samples across product lines, empowering engineering teams to:

- Reduce development cycles

- Minimize service campaigns

- Validate design assumptions with high-quality field data

Our customers routinely collect between 30 and 300 discrete data elements per machine—fueling insights no survey, user group, or anecdotal feedback can match. Traditional customer relationships remain vital, but data turns them from your primary input into a powerful complement.

Integrate Seamlessly

Connect telematics data directly into your warranty systems, CRM, and analytics environments using modern REST APIs.

As Software-Defined Machinery (SDM) becomes the industry standard, your connectivity needs increase. LHP’s platform supports full configuration management, including Firmware Over-The-Air (FOTA) updates—helping you reduce support costs while elevating the customer service experience.

Stay Laser Focused

On What Matters

No two OEMs build products alike—and your telematics experience shouldn’t be generic either. Beyond basic J1939 engine data, every manufacturer requires a unique view of operational insights. LHP’s configurable user interface ensures your teams see only the metrics that matter.

Examples of customer-specific insights:

- Concrete mixers: water consumption, drum rotation, and discharge data

- Material spreaders: hopper fill levels and work hours with clutches engaged

- Compressors: dry and wet side pressure transducer data for belt wear analysis

Your machines tell a story. LHP ensures you capture the information that drives product quality, customer loyalty, and long-term growth.